Andrew Vilcheck

Chester County

Painting, Home Repairs, Pressure-washing, Drainage, Hardscaping, Landscaping, Chimney Painting & Repairs, Stucco and Masonry Repairs

Servicing Chester County

and Surrounding Areas

Register # PA 045291

Andrew Vilcheck

93 Chester Avenue

Coatesville, PA 19320

ph: 484-888-2326

agvilche

- HOME

- Contact Form

- Painting (Interior)

- Drywall Repairs / Installation

- Painting (Exterior)

- Deck Staining

- Chimney Repairs / Painting

- Stucco Application (Repair / Paint)

- Paver Patios / Hardscapes / Repairs

- Paver Walkway Overlays

- Retaining Walls

- Mobile Home Supports & Skirting, Wooden Handrails & Step Repairs, Bilco Doors

- Pressure Washing

- Belgium Block and Paver Edgers

- Small Retaining Walls

- Mortar Repointing, Repairs to concrete Ramps and Walkways

- Wrought Iron Handrail Painting and Bilco Doors

- Drainage/Erosion Control

- Mulching

- Flower Beds Rock Gardens and Planting

- Pruning / Ornamental Grass

- Renovation of old beds

- Trees and Shrub Planting

- Brush and Tree Clearing

- Basement Waterproofing / Floor Epoxy

- About Me

Basement Waterproofing / Floor Epoxy

Ames Blu Max Masonry Waterproofer

There is a masonry waterproofing product that has recently come out with a "New White" version. It is Ames Blu Max. It is a thick rubberized masonry water proofer that can be applied to new block walls or older walls that have been previously painted.

The yellow discolorations on the walls is where water has been seeping through.

The walls must first be scraped clean of loose cement.

There is still efflorescence and dirt to wash from the surface.

I used Cleaning Vinegar or..."White Vinegar"

I scrubbed the walls down with it and then rinsed the vinegar off several times with fresh water. I then repeated the process.

The walls were allowed to dry for a minimum of 24 hours before applying the Ames Blu Max. There is a six hour recoat time. The directions call for a minimum of two coats. After the first coat was dry I could still see some yellow coming through. The second coat covered most of them.

After the second coating was thoroughly dry. I could still see yellowing in a few spots. I applied a liberal third coat over those areas.

The floors were cleaned and prepared the same way. After that, I applied a coating of "Seal Krete Lockdown" concrete bonding primer to the floor. This product is a preparatory material used to condition the floor prior to adding a top coat.

There is a two hour wait before applying the top coat.

The top coat used was Seal Krete Epoxy seal concrete and garage floor paint. Two coats are required. There is a 6 hour recoat time.

**************************************************************************

Professionally I apply coatings to basement walls and floors to waterproof and seal. However, there are companies that specialize only in basemement waterproofing. They are much more extensive with their procedures. If a basement has a substantial "water issue" it would be best to consult with one of them.

**************************************************************************

This house is about ten years old. The basement walls have never been coated. This condition is ideal for applying a masonry waterproofer or any coating for that matter.

The basement walls were pressure washed with a general cleaner. The next step is to etch them with an acid wash to remove efflorescence (Salts borne from the cement). Adequate ventilation and appropriate PPE is a must. The etch is rinsed off with clean water and allowed to dry thoroughly.

the coating is H&C Basement & Masonry Waterproofer by Sherwin Williams. Two coats were applied by roller and back-brushed. I used a third coat were pinholes persisted.

I have since switched to Ames Blu Max Rubberized waterproofer. This product has proven itself to be superior to the other products on the market.

**************************************************************************

Water leaking in, almost always comes through a crack in the wall. Sometimes it comes up through the floor. I have repaired basement walls and have installed exterior drainage to remedy leaking basements. In order to understand the problem an evaluation of the outside must be done as well as on the inside. In severe cases a trained specialist should be consulted.

**************************************************************************

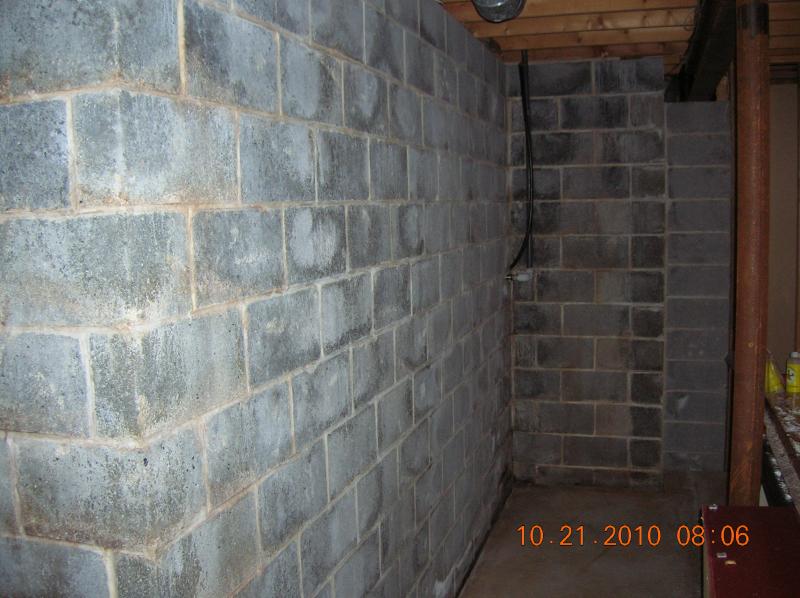

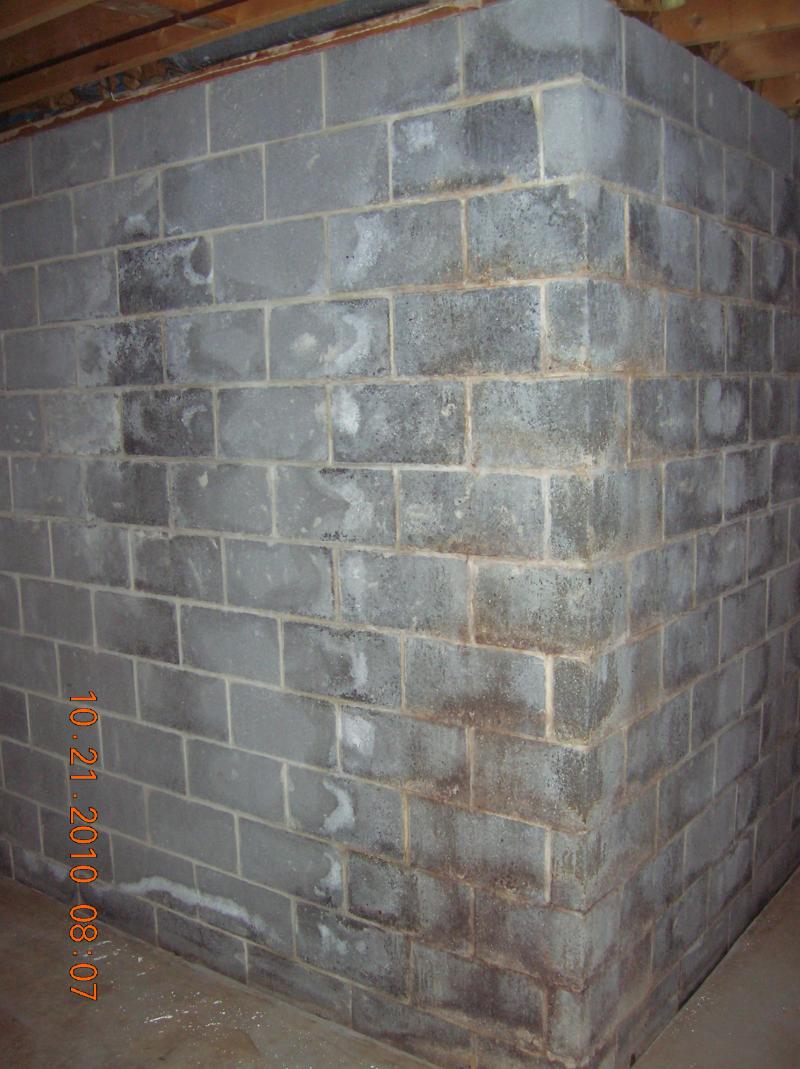

The photograph below shows a basement that has had over 20 years of water leakage. The walls are cracked and the paint is bubbling up due to efflorescence . Water streams in whenever there is a heavy rain.

Procedure

1)Outside evaluation Look to see if and how water is being directed into the basement from the outside. Sometimes the problem can be rectified through: french drains, drainpipe installation, or by grading topsoil to alter the course of rainwater. The problem may be as simple as a loose downspout.

2) Inside evaluation Locate where water is coming in to see exactly where the water is coming in. Do the walls or floor have cracks? Is the paint on the wall bubbling? Is the wall covered with mold or mildew. Is there a dehumidifier running?

3) Wait and See After a repair or change has been made, one must see if the problem has been eliminated. Several adjustments may need to be made prior to application of waterproofer.

4) Here is the basic procedure for the waterproofing concrete.

Wall condition before the removal of old paint

After grinding away loose paint, cement patching begins

After grinding, a hydraulic cement patching compound was used to fill cracks and holes. In this basement two coats of Drylok have been applied along the bottom edge to give extra protection before coating the whole wall with two more coats. Drylok is best used on untreated surfaces.

Sometimes leaks persist after this application. In this case a french drain containing a perforated 4" corex pipe was installed outside the window at a depth of two to three feet. The depth of the pipe was determined by the grade needed to take the water out to the street.

Two coats of Drylok were applied to ensure all pinholes were filled.

Here is another location in the cellar

After several rainfalls, There were a few spots that needed additional applications. Sometimes leaks persist and diligence is the only way to stop them.

After several rainfalls, There were a few spots that needed additional applications. Sometimes leaks persist and diligence is the only way to stop them.

Andrew Vilcheck

93 Chester Avenue

Coatesville, PA 19320

ph: 484-888-2326

agvilche